Tips and Tricks to Managing Supplier Performance

Why is it important to measure supplier performance?

Measuring supplier performance ensures your organization is getting what it’s paying for. The majority of contracts experience problems during post-award periods, including cost overruns and schedule delays. To add fuel to fire, contract performance is a highly visible phase of the acquisition process. Therefore, proper monitoring of suppliers can allow procurement professionals to add value to their agency. Procurement professionals can also gain external recognition from management, as a direct result of closely monitoring supplier performance.

So, how do procurement professionals make measuring supplier performance easy?

Invest in your Contracts Early

Solid supplier performance begins with clear specifications. At the very beginning of the procurement cycle, it is imperative that there is a statement or scope of work that directly outlines all expected milestones and deliverables. Additionally, once the contract is awarded, the contractor should be consulted again to ensure they understand the full deliverables required of them.

However, before contractor can be awarded and consulted, a solicitation must be issued. Investing in your contracts means providing standard contract templates at the beginning of the bidding phase. This can be included in a standard template for solicitations, which will not only streamline your bidding process, but also minimize the surprises that suppliers can expect in the final agreement.

Creating a contract that you would be proud of to share with your peers will pay off in leaps and bounds when you are to measure supplier performance.

Standardize Supplier Management Evaluations

The first step to measuring supplier performance is to create and share formal evaluations methods to be used universally among all suppliers of the agency. The following are a few steps that your agency can take to enforce best practices in supplier performance management:

- Quality of work and products (defects)

- Adherence to agreed upon schedule

- Meeting project milestones

- Cost control performance

- Administrative areas (invoicing, returns)

- Share and discuss with supplier

Once you create these standards of measurement (what qualifies as good performance or bad performance), retain the found data or information for future contracts with the same supplier, and for comparison with past or future suppliers. Supplier scorecards are just one way to create standard and meaningful measurements of supplier performance.

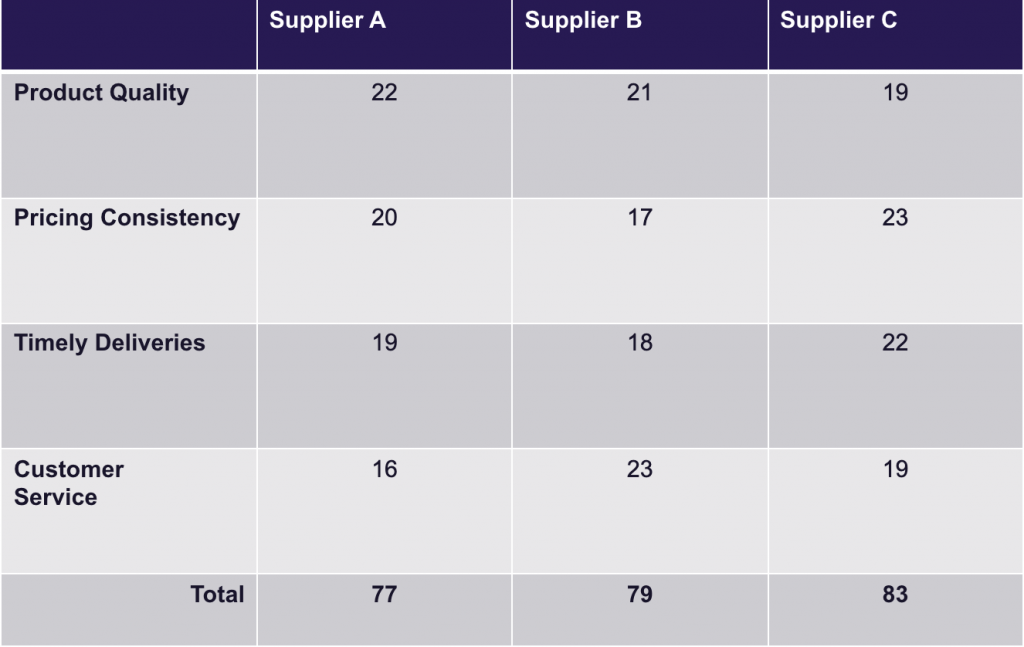

Supplier Scorecards

Supplier scorecards are considered to be a best practice in many industries. Often used for key suppliers or commodities, a supplier scorecard assigns a numeric score to a supplier’s performance. Abbreviated and easy-to-read fact sheets, like the one below, allows multiple suppliers within a category to be easily measured against each other.

Keeping a database or collection of these score cards can also lead to more informed purchasing decisions in the future, awarding suppliers with the highest scores in performance. Additionally, a scorecard can be used to measure a supplier’s performance in key focus areas, like sustainability. Below, a graphic shows other key corporate social responsibility (CSR) areas that an agency may want to use supplier scorecards to report on. Tracking and awarding efficiencies in these areas lead to higher opportunity, innovative practices, and external recognition.

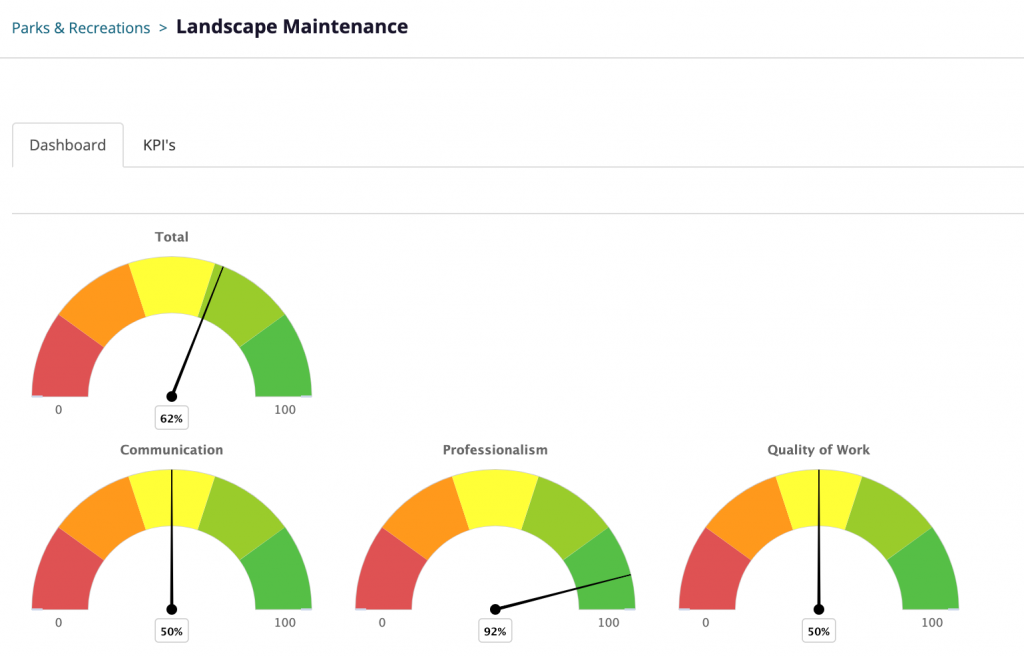

Key Performance Indicators

Key performance indicators (KPIs) are a type of supplier performance measurement that evaluates the success of a contract or partnership. KPIs simultaneously notify a contractor that your agency is watching and provides an opportunity for greater communication and collaboration. Furthermore, KPIs can be used as concrete data to back up conversations regarding performance and are imperative to consider for contract extensions.

Overall, there is no “magic bullet” when it comes to performance measurement. To create successful performance measurement, you and your agency should identify and define KPIs that are meaningful to your organization. These KPIs can be used to both monitor and improve performance, as long as the expectations are clear and set at the beginning of the project. Supplier management should be a priority for all purchasing organizations, and peers can be used as resources to determine what has worked in the past or for other organizations like yours.

The Mercell Source-to-Contract platform offers key supplier survey and KPIs monitoring technologies that could greatly benefit your organization. To speak with a member of our team, please click here and a member of our team will reach out to answer your questions about our platform, no strings attached!